Summary of Contents for LRE30451

Page 1: ...Service Digital Appliance TRAINING MANUAL ELECTRIC RANGE LRE30451 LRE30755 ...

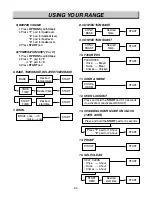

Page 8: ......

Page 9: ......

Page 11: ...j j j j LRE30451 LRE30755 ...

Page 67: ...8 1 APPENDIX A SCHEMATIC DIAGRAM OF PCB ...

Page 73: ...10 3 WARMNING DRAWER SELF CLEANING For Model LRE30755SW SB ST ...

Page 74: ...10 4 CLOCK DISPLAY ON CR Warming Zone CONV BAKE CONV ROAST For Model LRE30755SW SB ST ...

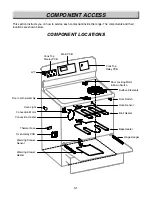

Page 90: ......

Page 91: ......

Page 92: ......