Copyright © Huawei Technologies Co., Ltd. 2020 All rights reserved.

1

Product Overview

Item

Product Model

Dimensions Without Packing

(H x W x D) (mm)

Optional Component

Indoor

unit

NetCol8000-A045D

2000 x 900 x 900

Electric heater and wet

film humidifier, differential

pressure sensor, water

leakage sensor,

temperature and humidity

sensor

NetCol8000-A045U

2000 x 900 x 900

NetCol8000-A060D

2000 x 1100 x 1000

NetCol8000-A060U

2000 x 1100 x 1000

NetCol8000-A090D

2000 x 1800 x 1000

NetCol8000-A120D

2000 x 2200 x 1000

Outdoor

unit

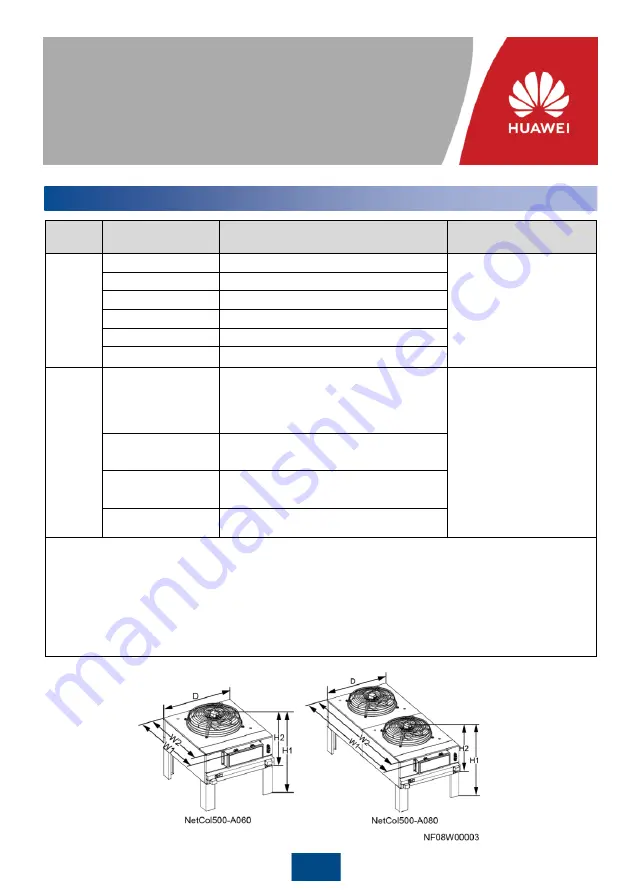

NetCol500-A060

Category B: D = 1094, W1 = 1356, W2 =

1217, H1 = 1107, H2 = 655

Category C: D = 1094, W1 = 1356, W2 =

1217, H1 = 1156, H2 = 725

Low-temperature

component

NetCol500-A080

D = 1094, W1 = 2186, W2 = 2047, H1 =

1107, H2 = 655

NetCol500-A120

D = 2189, W1 = 1356, W2 = 1217, H1 =

1107, H2 = 655

NetCol500-A110

D = 2189, W1 = 2250, H1 =1769

NetCol8000-A045 and NetCol8000-A060 is a single-system unit. NetCol8000-A090 and NetCol8000-

A120 is a dual-system unit.

NetCol500-A060, NetCol500-A080 and NetCol500-A110 are single-system units. NetCol500-A120 is

a dual-system unit.

A single-system indoor unit is used with a single-system outdoor unit; two single-system indoor units

are used together with a dual-system outdoor unit; a dual-system indoor unit is used with two single-

system outdoor units; a dual-system indoor unit is used with a dual-system outdoor unit.

1

Issue: 02

Part Number: 31500BLY

Date: 2020-04-20

NetCol8000-A (045, 060, 090, 120) In-

room Air Cooled Smart Cooling Product

Quick Guide