Summary of Contents for F01T500

Page 1: ...HUAWEI TECHNOLOGIES CO LTD F01T500 Quick Installation Guide Issue 07 Date 2017 05 03 ...

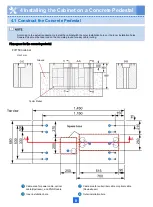

Page 19: ...With battery cabinet 4 Installing the Cabinet on a Concrete Pedestal 14 ...

Page 23: ...18 Unit mm 4 Installing the Cabinet on a Concrete Pedestal ...

Page 25: ...20 4 Installing the Cabinet on a Concrete Pedestal ...

Page 27: ...22 4 Installing the Cabinet on a Concrete Pedestal ...

Page 38: ...33 With power meter box ...

Page 40: ...35 With power meter box AC power cables AC power cables ...

Page 44: ...39 6 Routing Cables 6 3 Diagram of Cable Connections Between the RPS and MDF RPS Power Supply ...

Page 51: ...46 Route the input Cables of the AC RPR power supply 6 Routing Cables ...

Page 83: ...14 FAQs for Installation 78 ...

Page 84: ...15 FAQs for Installation 79 ...