USER MANUAL

32-00015-05

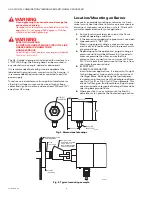

U2-S Model Combination Viewing

Head and Signal Processor

WARNING

WARNING

WARNING

Read the instructions before use. This control shall be

installed in accordance with the rules in force.

Additional versions of this manual are available online

at https://customer.honeywell.com/en-

US/Pages/default.aspx in Canadian French,

Portuguese, and German. Please enter 32-00015 in the

search box and choose Technical Literature from the

drop-down box.

AVERTISSEMENT

AVERTISSEMENT

Lire les instructions avant l'utilisation. Cette

commande doit être installée conformément aux lois

en vigueur. Des versions supplémentaires de ce manuel

sont disponibles enligne à

https://customer.honeywell.com/en-

US/Pages/default.aspx en français du Canada, en

portugais et en allemand. Veuillez inscrire 32-00015

dans le casier de recherche et choisissez

Documentation technique à partir du menu déroulant.

WARNUNG

Lesen Sie vor der Verwendung die Anweisung. Diese

Konsole muss entsprechend den geltenden

Vorschriften installiert werden. Zusätzliche Versionen

dieses Handbuchs sind online unter

https://customer.honeywell.com/en-

US/Pages/default.aspx in Frankokanadisch,

Portugiesisch und Deutsch verfügbar. Bitte geben Sie

im Suchfeld 32-00015 ein und wählen Sie Fachliteratur

im Drop-Down Menü aus

ATENÇÃO

Leia as instruções antes de usar. Esse controle tem que

ser instalado de acordo com as normas vigentes.

Outras versões desse manual estão disponíveis online

em https://customer.honeywell.com/en-

US/Pages/default.aspx em francês do Canadá,

português e alemão. Insira 32-00015 em cada caixa e

selecione Literatura Técnica na caixa suspensa.

Disposal and Recycling

Waste electrical products should not be disposed

of with general waste. Please recycle where these

facilities exist. Check with your local authority for

recycling advice.

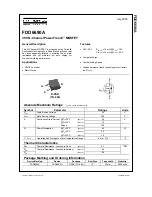

GENERAL INFORMATION

The Honeywell U2-101xS series model is a viewing head

and signal processor in a single enclosure intended for

use with a burner control system in Industrial Flame

Monitoring applications. There are several options

available (see Table 1 on page 2). Each model includes

one, two, or all three sensors, and can be ordered with

quick disconnect (non-PF Models DIV2,ZN2) or pigtail

external connection method (PF Models DIV1,ZN1).

Each sensor operates independently from another,

allowing adjustment of each sensor.

IMPORTANT

Flame monitoring systems are safety systems.

Please read this manual carefully and completely

before installation and before attempting adjust-

ments.

Only qualified personnel familiar with Flame

Safety System should carry out installation and

configuration.

U2 is certified to be used in prescribed manner.

Any modification or inappropriate installation or

operation may result in unsafe operation and will

void implied or expressed warranty.

Sensors

The UV tube detector has a peak response at 210 nm.

The IR solid state sensor has a peak response at 1400 nm.

The UV solid state sensor has a peak response at 310 nm.

Cabling Options (Sold Separately)

ASYU2S - Quick Disconnect (non-PF) models molded

connector cable assembly with 50 foot of C22S cable.

ASYU2S-100 - Quick Disconnect (non-PF) models molded

connector cable assembly with 100 foot of C22S cable.

ASYU2S-200 - Quick Disconnect (non-PF) models molded

connector cable assembly with 200 foot of C22S cable.

ASYU2S-300 - Quick Disconnect (non-PF) models molded

connector cable assembly with 300 foot of C22S cable.

C22S - Raw shielded 12 conductor, 22g, ITC, CIC

approved. Order by the foot.