® U.S. Registered Trademark

Copyright © 2000 Honeywell Inc. • All Rights Reserved

INSTALLATION INSTRUCTIONS

69- 1299

S8700B,D-F,J-M Direct Spark

Ignition Controls

APPLICATION

S8700 Direct Spark Ignition Controls are designed for

use in a wide range of gas-fired appliance applications

that require direct main burner ignition and flame safety

control of gas burners. The S8700 is used to ignite the

main burner, sense the flame and control the gas valve.

See Table 1 for the model that best meets your

application needs.

The S8700B,E,J,L models provide single rod flame

sensing (i.e., the spark rod also acts as the flame sense

rod). The S8700D,F,K,M models provide dual rod flame

sensing (i.e., the spark rod and flame rod are separate).

The S8700J,K,L,M models provide 30-second minimum

time delay between application of 24V power to the

control and initiation of the trial for ignition period for

applications that require prepurge. All models have an

LED status indicator.

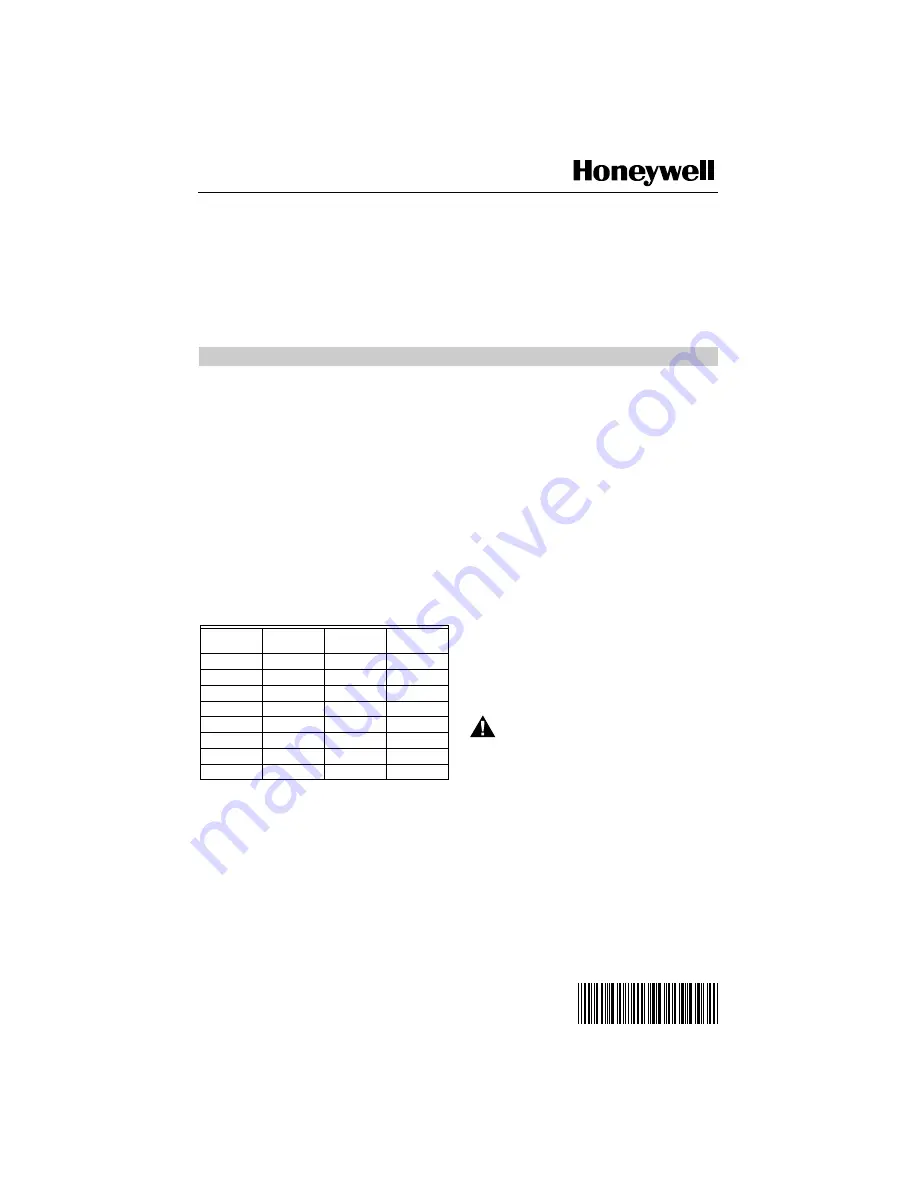

Table 1. S8700 Models.

SPECIFICATIONS

Electrical

Input Voltage: 24 Vac (20.5 Vac minimum to 28.5 Vac

maximum) at 60 Hz.

Current Draw: 0.15A maximum in run mode at 24 Vac.

Thermostat Anticipator Setting: 0.15A plus actual valve load.

Valve Output: 2.0A maximum run; 6.0A maximum

inrush at 24 Vac.

Alarm Output: 0.5A maximum resistive load (Output is

positive phase, one-half wave rectified, 24 Vac).

Spark Output: 14 KV minimum into 25 picofarad

capacitive load.

Environmental

Ambient Operating Temperature: -40°F to +175°F

(-40°C to +79°C).

Relative Humidity: 5% to 95% at 95°F (35°C),

noncondensing.

Ignition Sequence/Flame Sense

Prepurge: See Table 1.

Ignition Trials to Lockout: See Table 1.

Trial for Ignition Times: 4.6, 6.6, 11.1 or 21.1 second

nominal available.

Between Trial Purge: 30 second minimum

(S8700E,F,L,M only).

Auto Reset from Lockout: 60 minutes minimum

(S8700E,F,L,M only).

Flame Failure Re-ignition Time: 0.8 second maximum

at 1 microamp flame current.

Flame Current:

Minimum Threshold: 1 microamp.

Appliance Application: 2.5 microamp minimum recom-

mended under all appliance operating conditions.

Approvals:

CSA International Design Certified to ANSI Z21.20,

Report Number C2030026.

PLANNING THE INSTALLATION

WARNING

Fire or Explosion Hazard.

Gas leaks can cause property damage,

severe injury or death.

Follow these warnings exactly:

Plan the installation using the following outline.

Plan for frequent maintenance as described in

the Maintenance section.

Review the following conditions that apply to your

specific installation and take the precautionary steps

suggested.

Model

Flame

Sense

Trials for

Ignition

Prepurge

(seconds)

S8700B

1-rod local

1

0

S8700D

2-rod remote 1

0

S8700E

1-rod local

3

0

S8700F

2-rod remote 3

0

S8700J

1-rod local

1

30 minimum

S8700K

2-rod remote 1

30 minimum

S8700L

1-rod local

3

30 minimum

S8700M

2-rod remote 3

30 minimum

Summary of Contents for S8700 Series

Page 11: ...11 69 1299 ...