466-1534G • August 2006

Copyright © 2006, GE Security Inc.

Indoor/Outdoor PIR Motion Sensors

Installation Instructions

Introduction

This is the GE

Indoor/Outdoor PIR Motion Sensors Installation

Instructions

for model numbers:

• 60-639-95R (indoor)

• 60-639-95R-OD (outdoor)

• 60-639-43-EUR (indoor, not investigated for use by UL)

• 60-639-43-ERT-OD (outdoor, not investigated for use by

UL)

Passive-infrared (PIR) motion sensors detect movement within a

specific area by sensing the infrared energy emitted from a body

as it moves across the sensor’s field of view, causing a tempera-

ture change in the sensor’s zones. When the sensor detects this

motion, it transmits an alarm signal to the control panel.

Use the indoor sensors to protect large areas and open floor plans

or as backup protection for door/window sensors.

Use the outdoor sensors to identify motion in a protected outdoor

area. Detected motion in this protected area can sound chimes or

turn on outside lights. Do not use the outdoor sensors for intru-

sion protection.

Features include:

• 35 by 40 ft. (10.7 x 12.2 m) coverage area for standard and

optional pet alley lenses;

• masking kit to block portions of the coverage area;

• three-minute transmitter lockout time after an alarm to

extend battery life;

• cover-activated tamper (an optional wall-activated tamper is

provided);

• supervisory signal transmitted every 64 minutes to the

control panel;

• sensor low battery reports (trouble) to the control panel; and

• field-selectable sensitivity options.

Indoor sensor installation

Use the following installation guidelines:

• If possible, mount the sensor within 100 ft. (30.5 m) of the

panel. While the transmitter may have a range of 500 ft.

(152.4 m) or more out in the open, the environment at the

installation site can have a significant effect on transmitter

range.

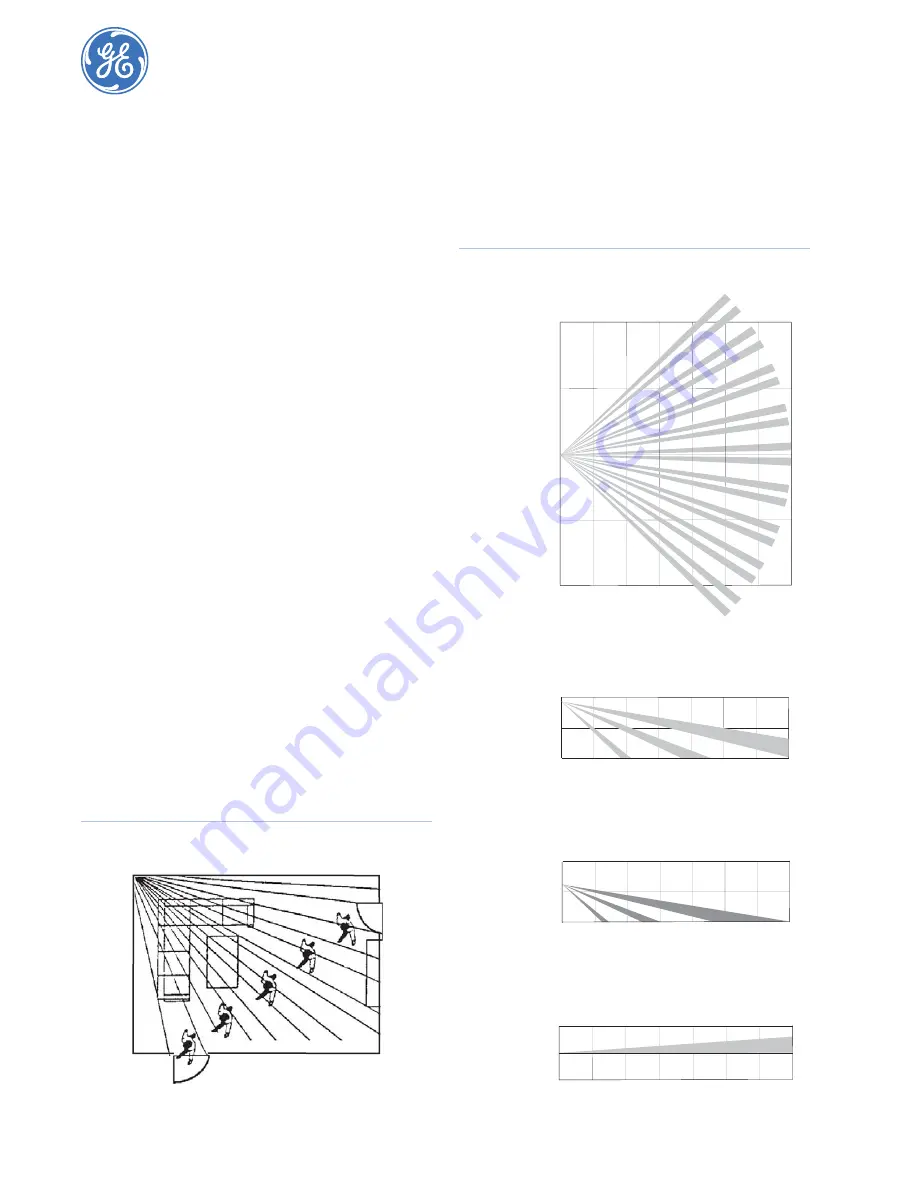

• Position the sensor to protect an area where an intruder is

most likely to walk across the detection pattern. (

Figure 1

).

Figure 1. Overhead detection pattern

• Mount the sensor between 5 and 8 ft. (1.5 and 2.4 m) from

the floor (

Figure 2

). We recommend a height of 7.5 ft. (2.3

m). Higher mounting provides better range, and lower

mounting provides better protection close to the sensor. See

Pet alley lens

on page 3.

Figure 2. Detection pattern

Side view with mounting height of 7.5 ft. (2.3 m)

Top view

20 ft.

6 m

20 ft.

6 m

10 ft.

3 m

10 ft.

3 m

0 ft.

0 m

5 ft.

1.5 m

15 ft.

4.5 m

25 ft.

7.5 m

35 ft.

10.5 m

5 ft.

1.5 m

15 ft.

4.5 m

25 ft.

7.5 m

35 ft.

10.5 m

5 ft.

1.5 m

15 ft.

4.5 m

25 ft.

7.5 m

35 ft.

10.5 m

5 ft.

1.5 m

15 ft.

4.5 m

25 ft.

7.5 m

35 ft.

10.5 m

0 ft. (0 m)

0 ft. (0 m)

0 ft. (0 m)

8 ft. (2.4 m)

8 ft. (2.4 m)

4 ft. (1.2 m)

4 ft. (1.2 m)

Side view with mounting height of 5 ft. (1.5 m)

Side view with pet alley lens and flush mount

8 ft. (2.4 m)

4 ft. (1.2 m)