Summary of Contents for FFLE3911QW

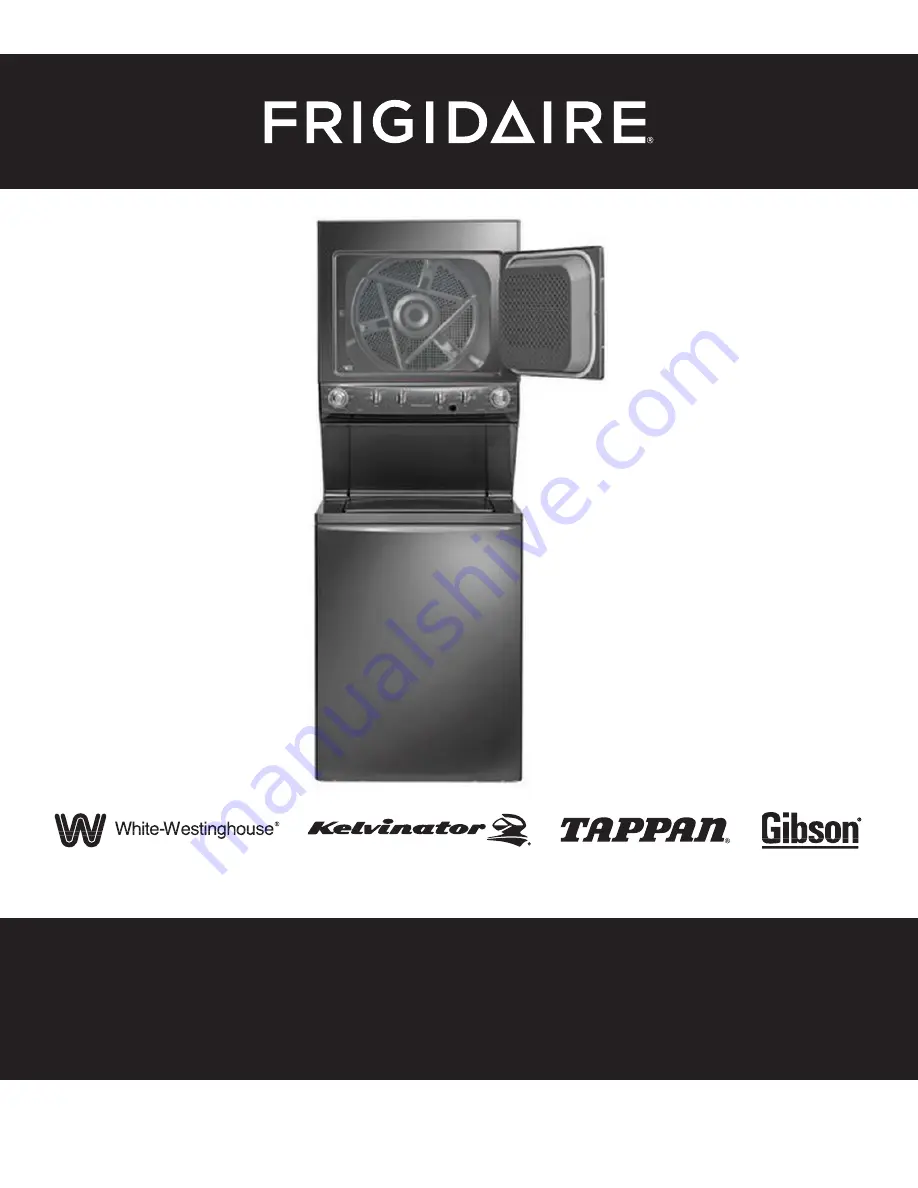

Page 1: ...Publication 5995666392 October 2015 Technical Service Manual Laundry Center ...

Page 2: ...I ...

Page 9: ...8 3 Product Features ...

Page 14: ...13 5 1 FFLE3911QW 5 1 1 Upper Cabinet Drum Heater 5 Exploded View and List of Parts ...

Page 17: ...16 5 1 2 Motor Blower Belt ...

Page 19: ...18 5 1 3 Control Panel ...

Page 21: ...20 5 2 FFLG4033QW 5 2 1 Upper Cabinet Drum Heater ...

Page 24: ...23 5 2 2 Motor Blower Belt ...

Page 27: ...26 5 2 3 Control Panel ...

Page 32: ...31 5 3 3 Wash Assembly POS NO DESCRIPTION 14 Screw 2 PLCS 15 Lock Hub Functional parts ...

Page 33: ...32 5 3 4 Cabinet Assembly ...

Page 69: ...68 User Interface of Laundry Center FFLG4033QW ...

Page 76: ...75 8 6 Wiring Diagram FFLE3911QW Electric Dryer Model ...

Page 77: ...76 8 7 Wiring Diagram FFLG4033QW Gas Dryer Model ...

Page 78: ...77 8 8 Wiring Diagram FFLE3911QW and FFLG4033QW Washer Model ...

Page 91: ...90 Wiring Diagram FFLE3911QW Wiring Diagram FFLG4033QW ...

Page 125: ...124 ...

Page 161: ...160 ...

Page 165: ...164 ...

Page 168: ...167 ...

Page 170: ...169 ...

Page 179: ...178 ...

Page 181: ...180 ...

Page 183: ...182 ...