8

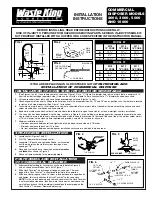

TROUBLESHOOTING

Before seeking repair or replacement, we recommend that you review the following:

LOUD NOISES:

(Other than those during grinding of

small bones and fruit pits): These are usually caused by

accidental entry of a spoon, bottle cap or other foreign

object. To correct this, turn off electrical switch and water.

After disposer has stopped, remove *splash guard, remove

object with long handled tongs, and replace *splash guard.

UNIT DOES NOT START:

Unplug power cord or turn

either the wall switch or breaker box switch to “OFF”

position, depending on your model and wiring configuration.

Remove stopper and/or *splash guard. Check to see if

turntable will rotate freely using a wooden broom handle. If

turntable rotates freely, replace *splash guard and check re-

set button to see if it has been tripped. Re-set button is red

and located opposite discharge elbow, near the bottom (see

8A). Push button in until it clicks and remains depressed.

If re-set button has not been tripped, check for shorted or

broken wire connecting to disposer. Check electrical power

switch, fuse box or circuit breaker. If wiring and electrical

components are intact, the unit may have internal problems

that require service or replacement.

*Splash guard not used on Top Control/Batch Feed unit.

IF TURNTABLE DOES NOT ROTATE FREELY:

Turn off disposer, then check for any foreign object lodged

between the turntable and grind ring. Dislodge object by

rotating table with a wooden broom handle and remove

object. (see 8B) If no foreign object is present, there may

be internal problems.

LEAKS:

If the unit leaks at the top, it may be due to:

1. Improper seating of sink flange (gasket centering, putty

or tightening).

2. Support ring not tightened properly.

3. Defective or improperly installed cushion mount.

If unit leaks at the waste elbow, leak may be due to im-

proper tightening of elbow flange screws.

Call our toll free Help Line with any questions

800-944-9044

CLEANING AND MAINTENANCE

DO NOT ATTEMPT TO LUBRICATE YOUR DISPOSER!

The motor is permanently lubricated. The disposer is self

cleaning and scours its internal parts with each use.

Mineral deposits from your water can form on the stainless

steel turntable, giving the appearance of rust. DO NOT BE

ALARMED, the stainless steel turntables used will not

corrode.

NEVER put lye or chemical drain cleaners into the disposer,

as they cause serious corrosion of metal parts. If used,

resulting damage can be easily detected an all warranties

are void.

8A

8B

560C525P02 REV A