www.Fisher.com

Fisher

™

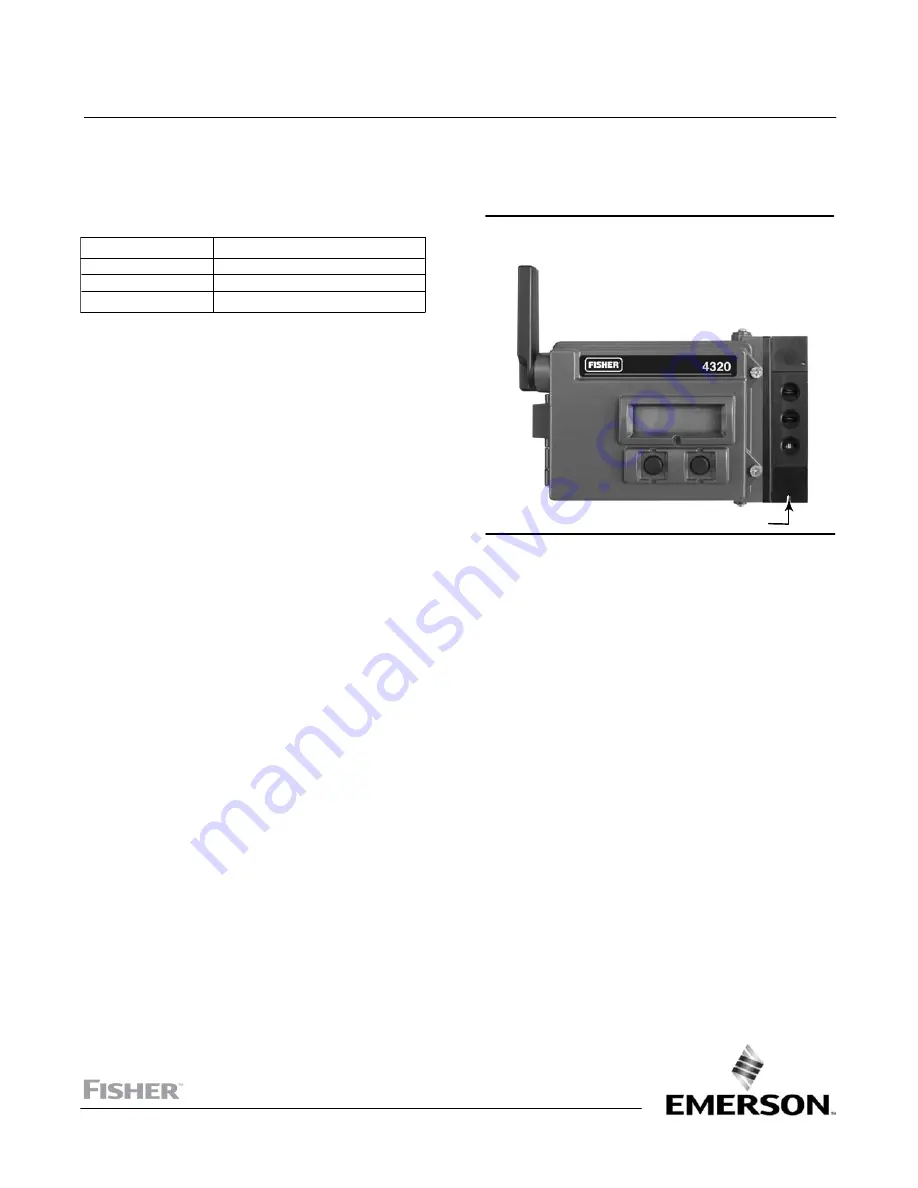

4320 Wireless Position Monitor

This manual applies to

Device Type

1308 (Hex) 4872 (decimal)

Device Revision

4

Firmware Revision

5

DD Revision

1

Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminology

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC Compliance

. . . . . . . . . . . . . . . . . . . . . . . . .

Educational Services

. . . . . . . . . . . . . . . . . . . . . . . . .

Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Standard and Extended Life

Power Module

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Unit Supplied with External

Power Option

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Setup

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Field Communicator

. . . . . . . . . . . .

Using AMS Wireless Configurator

or AMS Device Manager

. . . . . . . . . . . . . . .

Hazardous Area Classifications and

Special Instructions for “Safe Use” and

Installations in Hazardous Locations

. . . . . . . . .

Valve / Actuator Mounting

. . . . . . . . . . . . . . . . . . .

Sliding‐Stem (Linear) Actuators

(e.g. Fisher 667)

. . . . . . . . . . . . . . . . . . . . . .

Guidelines for Mounting on Quarter‐Turn

(Rotary‐Shaft) Actuators

. . . . . . . . . . . . . . .

Pneumatic Hookup Procedure for

On/Off Control Option

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Connections

. . . . . . . . . . . . . . . . . .

Wireless Communications

. . . . . . . . . . . . . . . . . . . . .

Basic Setup and Configuration

. . . . . . . . . . . . . . . . .

Using the Local User Interface

. . . . . . . . . . . . . . . .

Identifying Device Revision

. . . . . . . . . . . . . . .

Language Selection

. . . . . . . . . . . . . . . . . . . . .

Quick Position

. . . . . . . . . . . . . . . . . . . . . . . . . .

Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

X0899

Figure 1. Fisher 4320 Wireless Position Monitor, with

On/Off Control Option

ON/OFF CONTROL OPTION

Network

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrate

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Field Communicator

. . . . . . . . . . . . . . . .

Overview

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Tools

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Features

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Troubleshooting

. . . . . . . . . . . . . . . . .

Replacing the Instrument

. . . . . . . . . . . . . . . . . . . .

Instrument Removal

. . . . . . . . . . . . . . . . . . . . .

Replacing the Magnetic Feedback Assembly

. . . .

Replacing the Power Module

. . . . . . . . . . . . . . . . .

Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting Power Module Variables

. . . . . . . . .

Component Maintenance—On/Off Control Option 60

Spool Valve and Pneumatic Gasket Removal

.

Spool Valve and Pneumatic Gasket Installation 61

Pneumatic Interface and Gasket Removal

. . .

Pneumatic Interface and Gasket Installation

.

. . . . . . . . . . . . . . . . . . . . . .

Instruction Manual

D103621X012

4320

January 2018