1592006207 XB570L GB r1.1 23.03.2015 XB570L

1/20

XB570L

BLAST CHILLER - QUICK CHILL AND HOLD FUNCTION

CONTENTS

1.

PLEASE READ BEFORE USING THIS MANUAL ....................................................................................... 1

2.

SAFETY PRECAUTIONS ............................................................................................................................. 1

3.

GENERAL FEATURES ................................................................................................................................. 2

4.

MOUNTING & INSTALLATION ..................................................................................................................... 2

5.

ELECTRICAL CONNECTIONS .................................................................................................................... 2

6.

CONNECTIONS ............................................................................................................................................ 2

7.

FRONTAL PANEL......................................................................................................................................... 1

8.

QUICK START .............................................................................................................................................. 1

9.

HOW TO SELECT A CYCLE ........................................................................................................................ 6

10.

PARAMETERS ............................................................................................................................................. 7

11.

HOW A CYCLE IS DONE. .......................................................................................................................... 10

12.

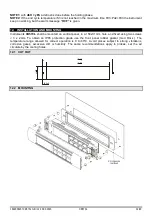

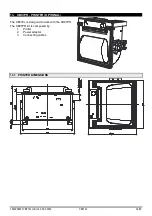

INSTALLATION AND MOUNTING ............................................................................................................. 12

13.

XB07PR - PRINTER (OPTIONAL) .............................................................................................................. 13

14.

ELECTRICAL CONNECTIONS .................................................................................................................. 14

15.

TTL SERIAL LINE ....................................................................................................................................... 15

16.

USE OF THE PROGRAMMING “HOT KEY “ ............................................................................................. 15

17.

ALARM SIGNALS ....................................................................................................................................... 15

18.

TECHNICAL DATA ..................................................................................................................................... 16

19.

STANDARD VALUE OF THE CYCLES. ..................................................................................................... 16

20.

STANDARD VALUES OF THE PARAMETERS. ........................................................................................ 17

1. PLEASE READ BEFORE USING THIS MANUAL

•

This manual is part of the product and should be kept near the instrument for easy and quick

reference.

•

The instrument shall not be used for purposes different from those described hereunder. It cannot be

used as a safety device.

•

Check the application limits before proceeding.

•

Dixell Srl reserves the right to change the composition of its products, even without notice, ensuring

the same and unchanged functionality.

2. SAFETY PRECAUTIONS

•

Check the supply voltage is correct before connecting the instrument.

•

Do not expose to water or moisture: use the controller only within the operating limits avoiding sudden

temperature changes with high atmospheric humidity to prevent formation of condensation

•

Warning: disconnect all electrical connections before any kind of maintenance.

•

Fit the probe where it is not accessible by the End User. The instrument must not be opened.

•

In case of failure or faulty operation send the instrument back to the distributor or to “Dixell S.r.l.” (see

address) with a detailed description of the fault.

•

Consider the maximum current which can be applied to each relay (see Technical Data).

•

Ensure that the wires for probes, loads and the power supply are separated and far enough from each

other, without crossing or intertwining.

•

In case of applications in industrial environments, the use of mains filters (our mod. FT1) in parallel

with inductive loads could be useful.