Model 2400

June 2019

Instruction Manual

D104470X012

Model 2400 In-line Duct Flame Arrestor

North America

Only

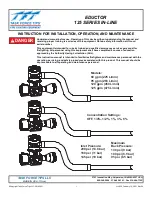

Figure 1

. In-line Duct Flame Arrestor

Table of Contents

Introduction ............................................................................1

Specifications ........................................................................2

Principle of Operation ............................................................2

Factors Affecting Flame Arrestor Performance ......................2

Installation .............................................................................3

Maintenance ..........................................................................4

Parts Ordering .......................................................................4

!

WARNING

Failure to follow these instructions or to

properly install and maintain this equipment

could result in an explosion, fire and/or

chemical contamination causing property

damage and personal injury or death.

Enardo detonation flame arrestor must

be installed, operated and maintained

in accordance with federal, state and

local codes, rules and regulations

and Emerson Process Management

Regulator Technologies Tulsa, LLC

(Emerson) instructions.

Failure to correct trouble could result in a

hazardous condition. Call a qualified service

person to service the unit. Installation,

operation and maintenance procedures

performed by unqualified person may

result in improper adjustment and unsafe

operation. Either condition may result in

equipment damage or personal injury. Only

a qualified person must install or service the

detonation flame arrestor.

Product Description

This manual applies to the Model 2400 In-line Duct Flame

Arrestor which is intended for applications where the

maximum distance between the most distant system ignition

source and the connection flange of unprotected (hot) side

of the flame arrestor are with the limits indicated in the

installation section of this manual. This product is to be used

in Gas Group IIA flammable vapor applications where the

minimum Maximum Experimental Safe Gap (MESG) of the

stream is 0.035 in. / 0.90 mm or higher.

Product Identification and Marking

The product is provided with product identification

consisting of a nameplate and an appropriate warning label

in accordance with ISO 16852:2016. Please review this

information prior to installing the product.

Construction

The Model 2400 In-line Duct Flame Arrestor consists of a

housing assembly consisting of 24 in. Sch. 40 nominal pipe

and plate flanges available in Carbon steel, Stainless steel

or Hastelloy

®

. The flame element is available in 304, 316

Stainless steel or Hastelloy

®

. The housing is fitted with 1/2 in.

threaded pipe couplings which are used for the installation of

a temperature sensor on the unprotected side of the arrestor.

A temperature sensor must be used in order for this product

to comply with ISO 16852 guidelines. Standard construction

consists of a 10 in. / 254 mm face-to-face dimension.

Introduction

Scope of the Manual

This Instruction Manual provides instructions for installation,

operation, maintenance and parts ordering information for

the Model 2400 In-line Duct Flame Arrestor.

Hastelloy

®

is a mark owned by Haynes International, Inc.