Reviews:

No comments

Related manuals for EWM09312

266

Brand: V-ZUG Pages: 12

TA4560

Brand: TAKARA Pages: 2

00110229

Brand: Xavax Pages: 12

039-8708-0

Brand: Simoniz Pages: 8

111363

Brand: Xavax Pages: 2

MCSLRW

Brand: Magic Chef Pages: 6

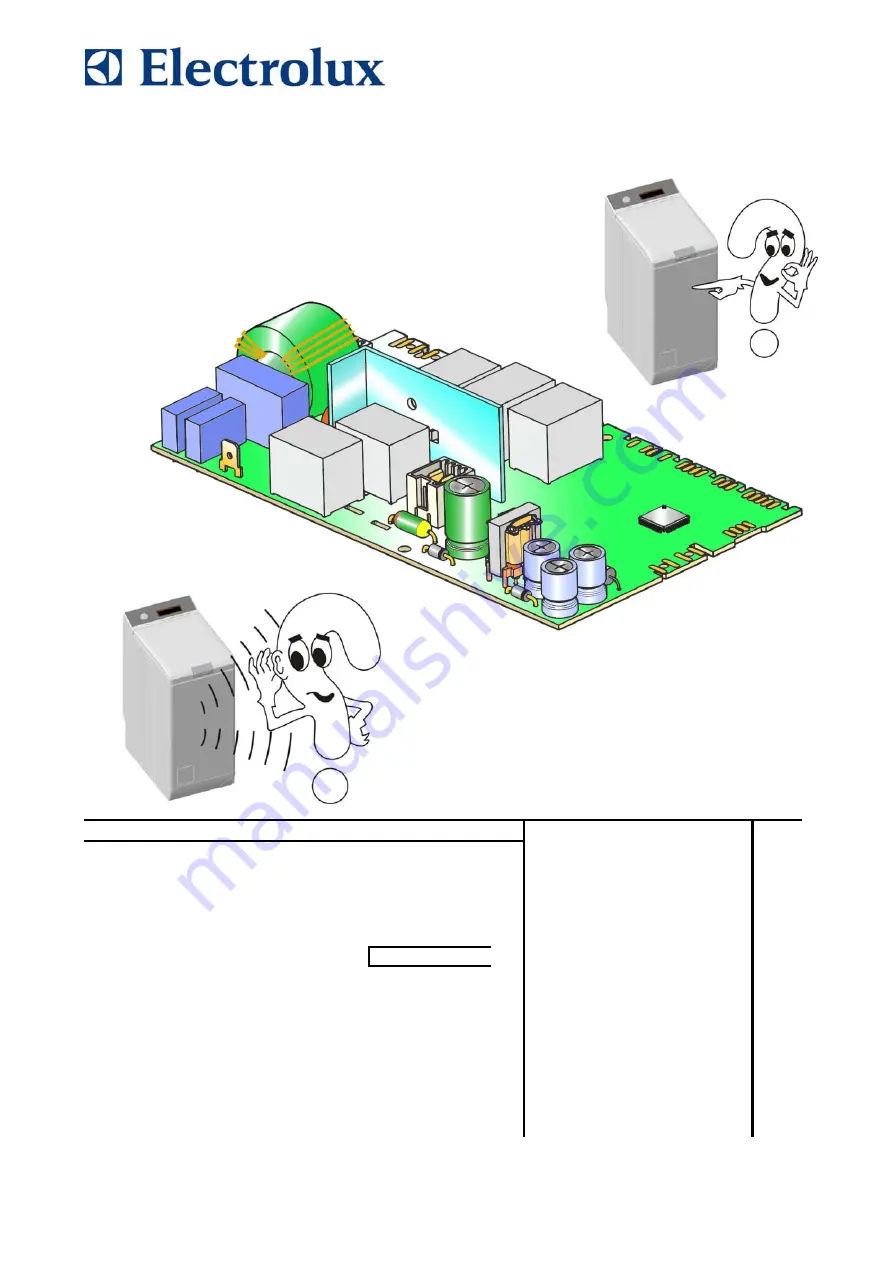

EDS

Brand: Electrolux Pages: 40

EPWD15T

Brand: Electrolux Pages: 12

137147600 B (0906)

Brand: Frigidaire Pages: 20

137147900 A

Brand: Frigidaire Pages: 16

FAM155R1AA

Brand: Frigidaire Pages: 12

FDPW1

Brand: Frigidaire Pages: 3

49-90233

Brand: GE Pages: 12

49-90321

Brand: GE Pages: 36

49-90344

Brand: GE Pages: 12

DPVH8800GJ

Brand: GE Pages: 12

Profile SmartDispense SPBD880

Brand: GE Pages: 64

Profile SmartDispense SPBD880

Brand: GE Pages: 64