00011

Important:

Read and fol low

all Safety Rules

and In struc tions

Be fore Op er at ing

This Equip ment

MODEL NO.

944.627870

OWNER’S

MANUAL

• Assembly

• Operation

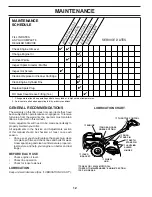

• Maintenance

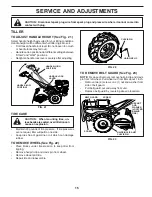

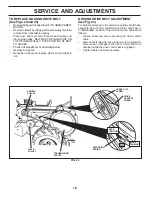

• Service and Ad just ments

• Repair Parts

850 SERIES

17 INCH TINE WIDTH

REAR TINE TILLER WITH

DUAL ROTATING TINES

Sears Canada, Inc., Toronto, Ontario M5B 2B8

Summary of Contents for 850 Series

Page 33: ...33 SERVICE NOTES ...

Page 34: ...34 SERVICE NOTES ...

Page 35: ...35 SERVICE NOTES ...

Page 36: ...PRINTED IN THE U S A 411772 02 02 07 CL 02488 ...