PRINTED IN U.S.A.

Operator's Manual

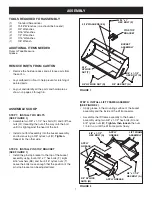

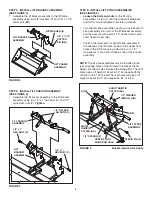

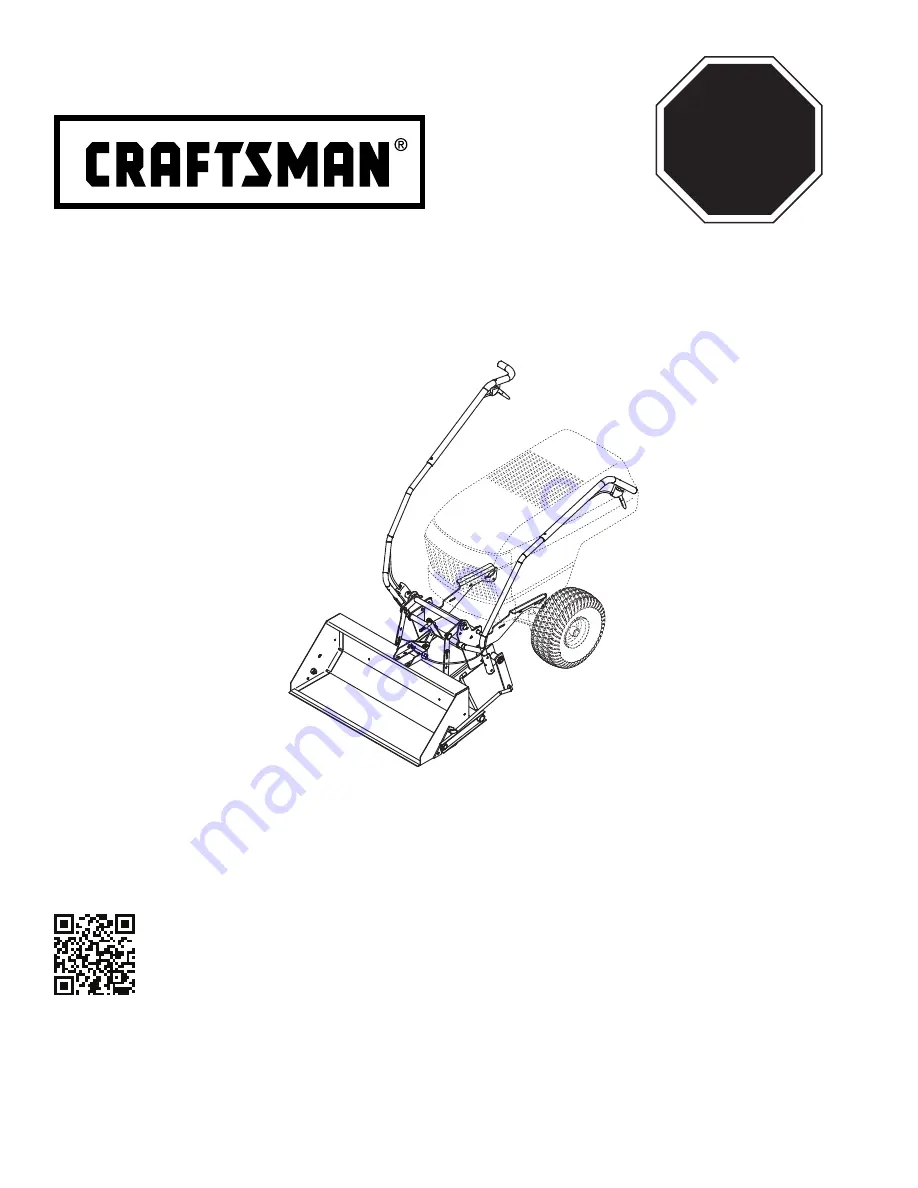

FRONT SCOOP TRACTOR ATTACHMENT

Model No. 486.248476

FORM NO. 40344 (03/19/15)

CAUTION:

Before using this product, read

this manual and follow all Safety

Rules and Operating Instructions.

• Safety

• Assembly

• Operation

• Maintenance

• Parts

STOP

DO NOT RETURN TO STORE

For Missing Parts or Assembly

Questions Call 1-866-576-8388

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

www.sears.com/craftsman

Want more information or assembly tips?

Scan with free ShowUHow Mobile App

available at iTunes Store or Google Play.

Summary of Contents for 486.248476

Page 22: ...22 NOTES ...