Reviews:

No comments

Related manuals for 315.175501

RF100/710

Brand: Felisatti Pages: 53

EBJ720K

Brand: Ryobi Pages: 24

054-8106-4

Brand: MasterCraft Pages: 12

BBJ9000

Brand: BorMann Pages: 25

BJA 300

Brand: Triton Pages: 9

Top 21

Brand: Lamello Pages: 120

96 30 49

Brand: Westfalia Pages: 28

38648

Brand: Chicago Electric Pages: 14

PFDFA 20-Li A1

Brand: Parkside Pages: 179

17539 - 6.0 Amp Plate Jointer

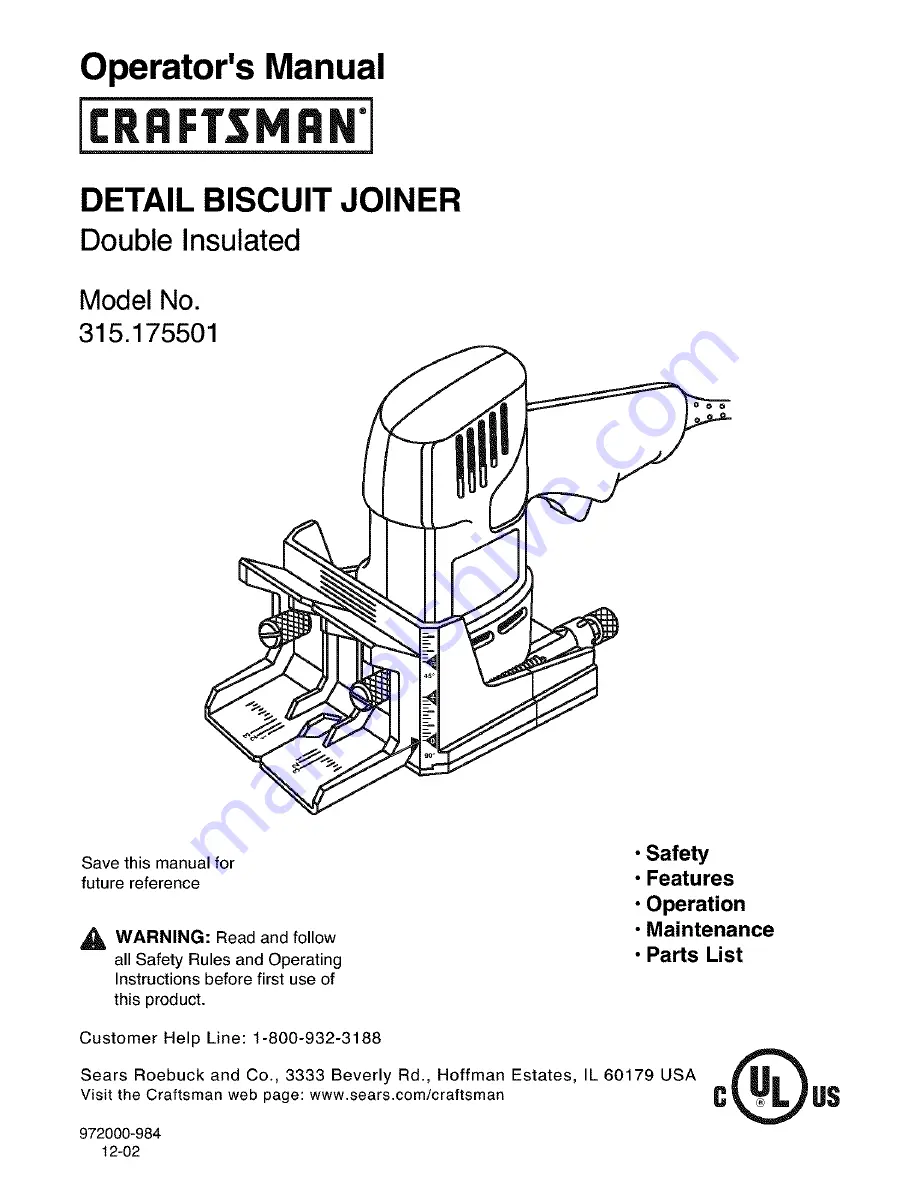

Brand: Craftsman Pages: 26

DW682K

Brand: DeWalt Pages: 64

17550 - 3.5 Amp Detail Biscuit Jointer

Brand: Craftsman Pages: 26

315.175500

Brand: Craftsman Pages: 24

BM018

Brand: 909 Pages: 16

T31999

Brand: Grizzly Pages: 32

G0490X

Brand: Grizzly Pages: 2

G0490

Brand: Grizzly Pages: 68

BJK-1010U

Brand: Ozito Pages: 10