Reviews:

No comments

Related manuals for 113.20680

1902

Brand: Makita Pages: 2

1912B

Brand: Makita Pages: 3

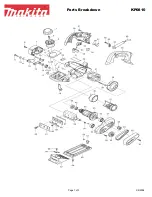

KP0810

Brand: Makita Pages: 3

1900B

Brand: Makita Pages: 12

KP312

Brand: Makita Pages: 3

KP0800

Brand: Makita Pages: 8

KP0810

Brand: Makita Pages: 11

1911B

Brand: Makita Pages: 44

N1923B

Brand: Makita Pages: 60

M1902

Brand: Makita Pages: 19

KP0800

Brand: Makita Pages: 56

BKP140

Brand: Makita Pages: 10

HG 1100

Brand: Makita Pages: 4

Platinum Series

Brand: Laguna Tools Pages: 42

PEH 30 A1 ELECTRIC PLANER

Brand: Parkside Pages: 25

EP 900

Brand: Far Tools Pages: 74

PHA 12 B2

Brand: Parkside Pages: 132

5240

Brand: Oliver Pages: 59