Information INF09/027 Rev. D

Endura AZ20 oxygen monitor

Pumped reference air unit

1 Introduction

This publication details the installation, connection and

maintenance of an ABB Pumped Reference Air Unit. This pump

supplies reference air to any of the following ABB oxygen probes:

AZ20, AZ25, AZ20/ZFG2 replacement, ZFG2 and ZGP2

4 pump models are available – see Table 1.1:

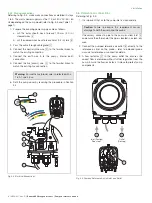

The internal air filter is a replaceable item (ABB part

number 0217463).

2 Safety

Information in this document is intended only to assist our

customers in the efficient operation of our equipment. Use of this

manual for any other purpose is specifically prohibited and its

contents are not to be reproduced in full or part without prior

approval of the Technical Publications Department.

2.1 Safety precautions

Please read the entire document before unpacking, setting up, or

operating this pump.

Pay particular attention to all warning and caution statements.

Failure to do so could result in serious injury to the operator or

damage to the equipment.

To ensure the protection provided by this equipment is not

impaired, do not use or install this equipment in any manner other

than that which is specified in this manual.

2.2 Health & Safety

Note.

The pump cannot be used with multiple probes

simultaneously.

Description

ABB Part Number

1

/

4

BSP (Metric) 230 V AC 50 / 60 Hz

AZ200 770

1

/

4

BSP (Metric) 115 V AC 50 / 60 Hz

AZ200 771

1

/

4

NPT (Imperial) 230 V AC 50 / 60 Hz

AZ200 772

1

/

4

NPT (Imperial) 115 V AC 50 / 60 Hz

AZ200 773

Table 1.1 ABB Pumped Reference Air Unit Part Numbers

To ensure that our products are safe and without risk to health,

the following points must be noted:

The relevant sections of these instructions must be read

carefully before proceeding.

Warning labels on containers and packages must be

observed.

Installation, operation, maintenance and servicing must

only be carried out by suitably trained personnel and in

accordance with the information given.

Normal safety precautions must be taken to avoid the

possibility of an accident occurring when operating in

conditions of high pressure and / or temperature.

Safety advice concerning the use of the equipment described

in this manual or any relevant Material Safety Data Sheets

(where applicable) may be obtained from the Company address

on the back cover, together with servicing and spares

information.